Next generation pipeline isolation

The TDW SHiiELD™ introduces Double Independent Isolation & Bleed (DiiB) technology as the new standard to meet the industry's demands, surpassing the capabilities of traditional double block and bleed systems.

Uncompromising safety. Unmatched throughput. Zero emissions.

With independently anchored modules, advanced leak-proof seals, and unparalleled bypass capabilities, SHiiELD™ minimizes downtime, eliminates emissions, and maximizes operational performance; all while enhancing environmental compliance and reducing risk.

Uncompromising safety. Unmatched throughput. Zero emissions.

Uncompromising safety. Unmatched throughput. Zero emissions.

Uncompromising safety. Unmatched throughput. Zero emissions.Energized seals

Uncompromising safety. Unmatched throughput. Zero emissions.

Uncompromising safety. Unmatched throughput. Zero emissions.

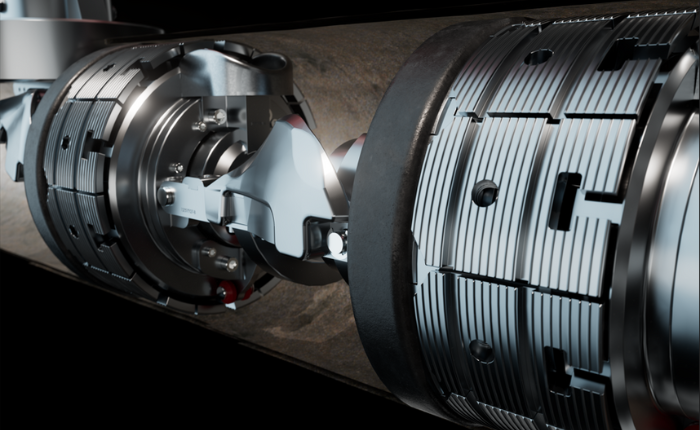

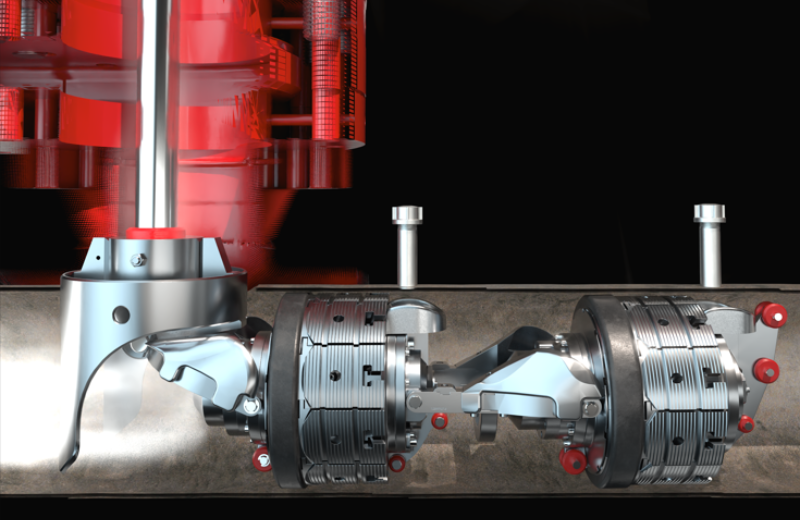

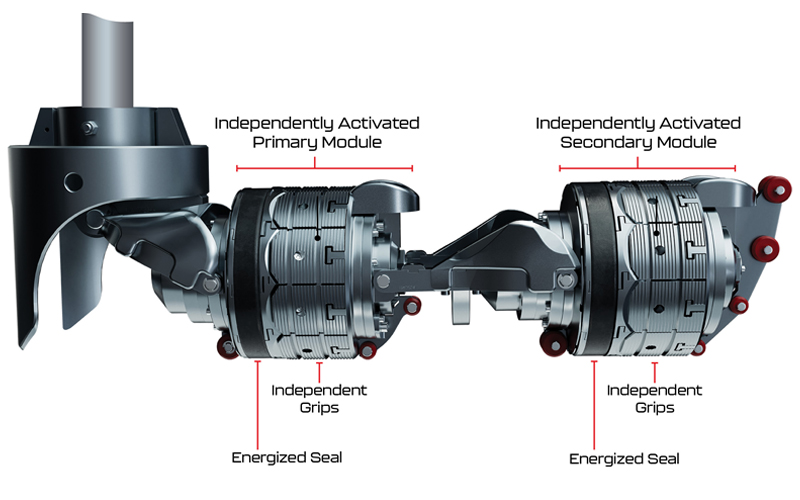

TDW SHiiELD™ is the industry’s first Double Independent Isolation & Bleed (DiiB) technology, redefining safety, and surpassing the capabilities of double block and bleed systems. SHiiELD™ is the only tool on the market that leverages two independently anchored modules to create true redundancy. Each independent module features energized seals that are electromechanically activated, achieving a leak-proof isolation every time.

The TDW SHiiELD™ achieves 4x more internal bypass during isolations, eliminating the need for operators to derate the pressure of their pipeline, or make additional taps; a significant industry advantage. Patented grip technology enables each plugging module to anchor independently inside the pipeline, removing stress from the control arm and allowing maximized bypass through the housing.

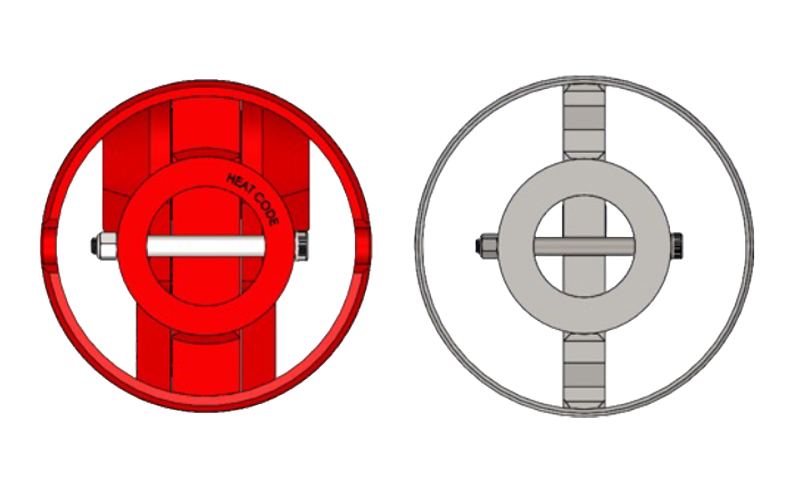

The TDW SHiiELD™ utilizes a next-gen seal that ensures a certified, leak-proof isolation, meeting strict environmental standards while reducing the carbon footprint of pipeline operations. Its efficient design minimizes energy use and lowers operational costs, promoting sustainable practices while raising the bar on performance.

Each TDW SHiiELD™ plugging module features an advanced energized seal that is electro-mechanically activated, delivering a certified, emission-free, leak-proof isolation you can rely on every time. Electro-mechanical actuation eliminates the need for hydraulics and allows the tool to be activated remotely, from outside of the ditch. By eliminating hydraulic hoses, this next-generation activation system reduces failure points, offering a more controlled and dependable sealing process.

The TDW SHiiELD™ is engineered for remote activation and monitoring, allowing the tool to be activated and monitored from outside of the ditch, minimizing personnel exposure. Active isolation monitoring provides real-time data on pressure, temperature, and flow, delivering actionable insights to improve decision-making and operational reliability.

The TDW SHiiELD™ features an innovative design that streamlines an operator’s time to isolate. Its independent plugging modules expand up to 20%, enabling faster setup, smooth kinematics, a certified seal on the first attempt, and a more efficient isolation process. By applying force directly to the plugging modules, SHiiELD™ minimizes stress on fittings, eliminating the need for additional engineering evaluations.

SHiiELD™ specifications

Pressure / Temperature

- 1480 psi

- Negative 10 C to plus 80 C (14 F to 176 F) Temperature formatting change.

Backward compatibility

- Standard STOPPLE® cutter

- Standard Hydraulic cylinder

- Standard STOPPLE® Train housing

- Standard SANDWICH® type valve

- STOPPLE® fittings

Uncompromising safety. Unmatched throughput.

The story behind SHiiELD™

Take the next step toward safer, smarter pipeline isolation today

Discover how the TDW SHiiELD™ can transform your operations.